01. High performance

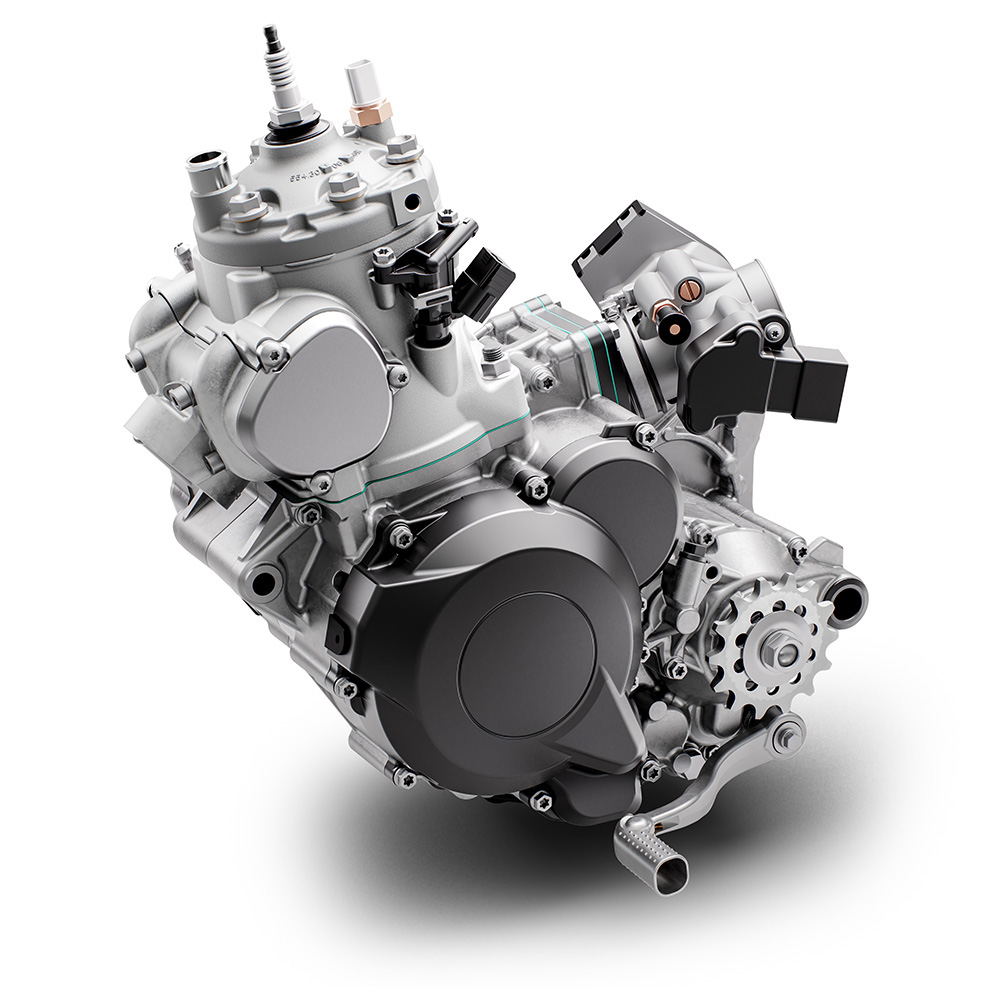

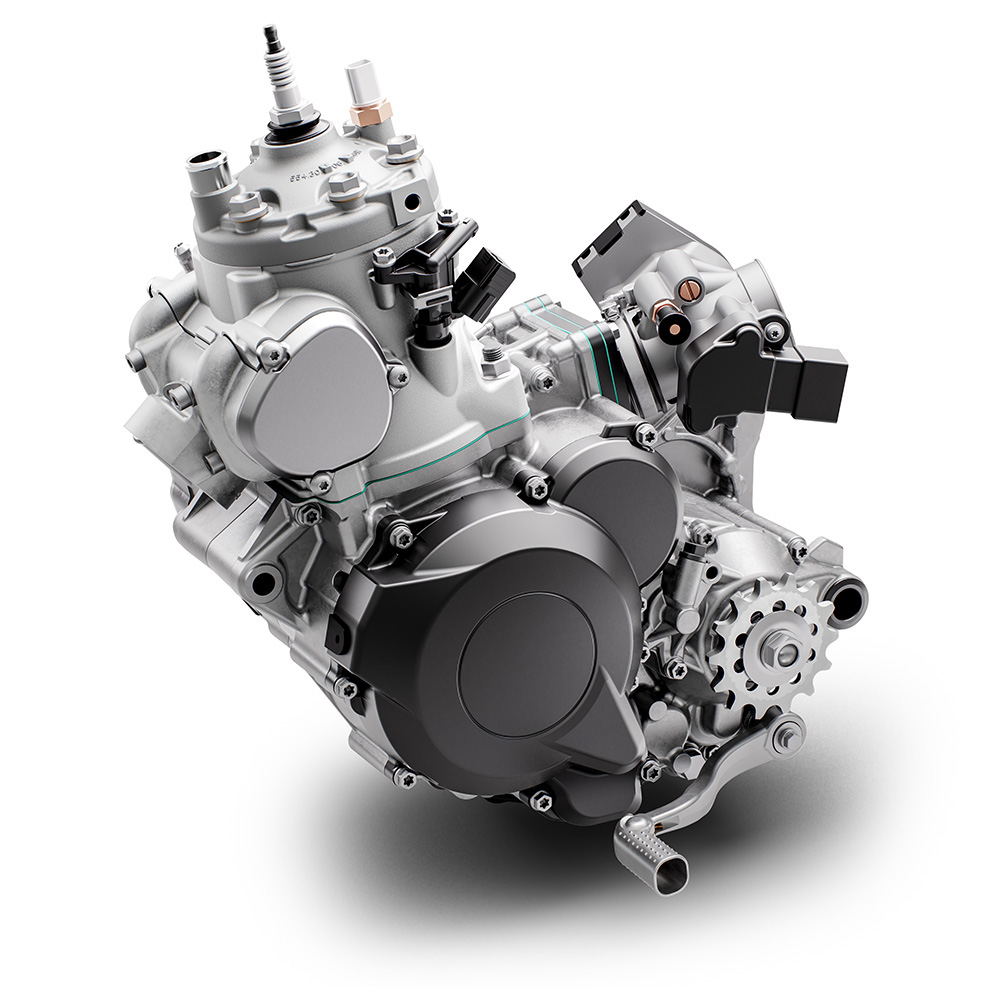

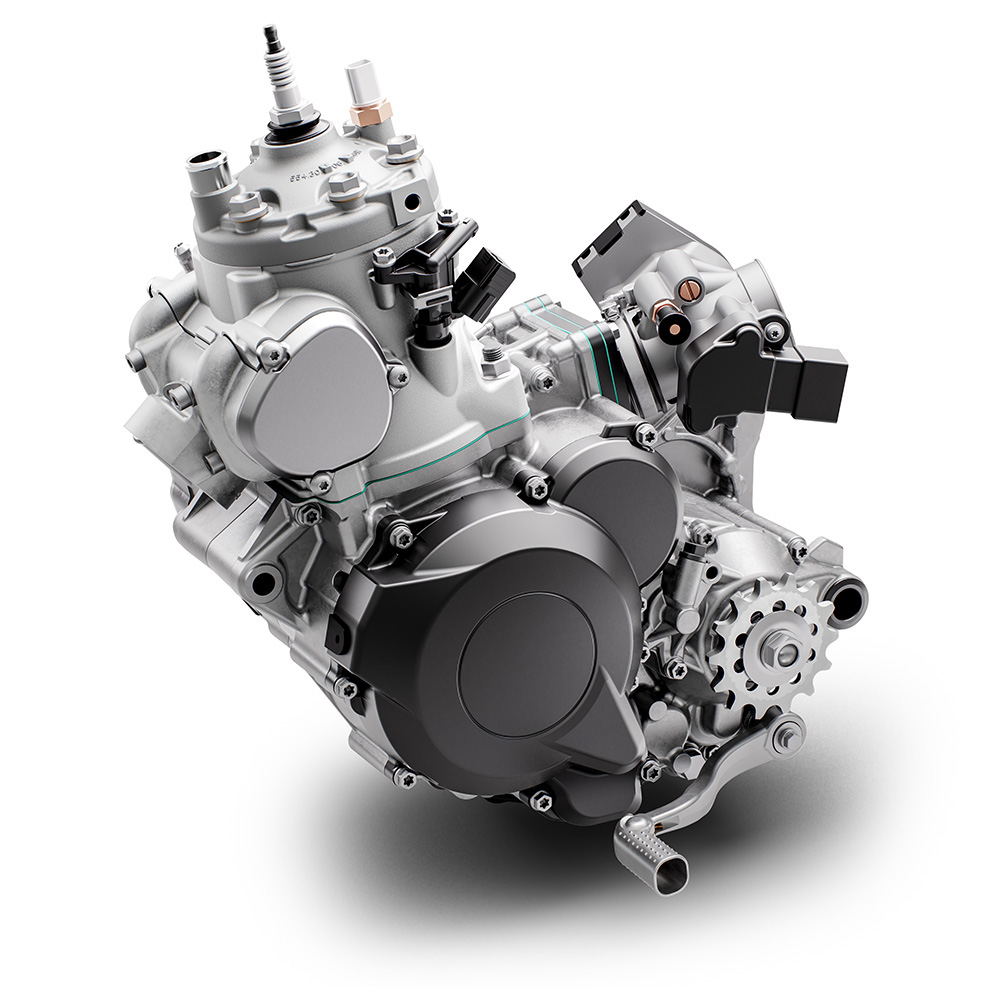

Engine

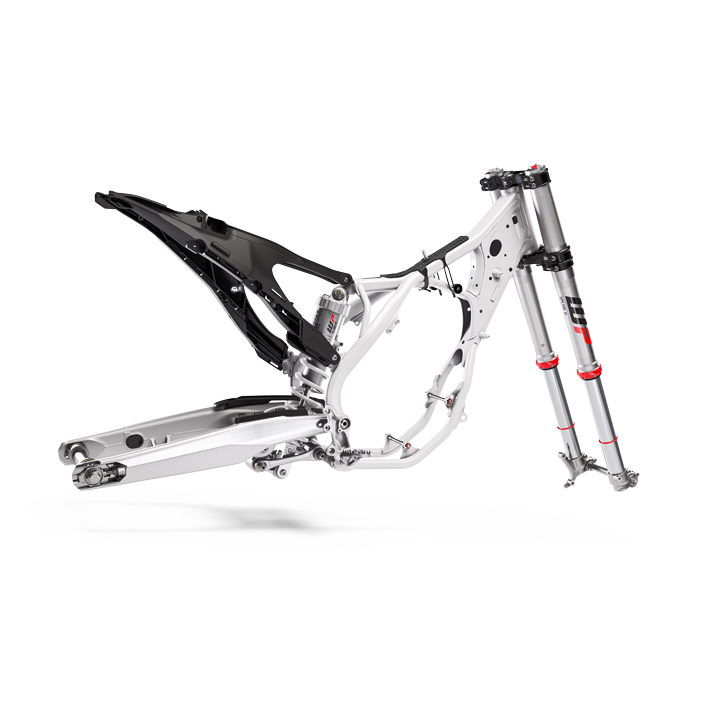

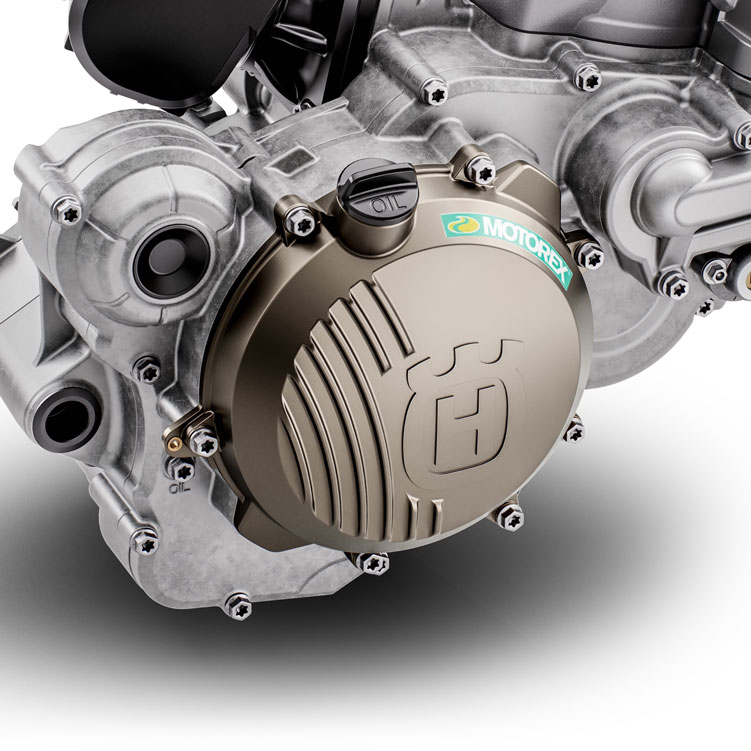

Arguably the best combination of power and weight, the TE 250 engine is a longstanding favourite with enduro riders. While technological advancements mean the TE 250 features a pioneering fuel injection system, it remains a low maintenance workhorse of an engine. Additionally, the TE 250 engine has an advanced construction featuring shaft arrangements precisely positioned for greater mass centralisation, a counter balancer shaft reducing vibration and a twin-valve controlled power valve for smoother power delivery.

Cylinder

The 66.4 mm bore cylinder in the TE 250 features a twin valve-controlled power valve system which delivers smooth and controlled power throughout the RPM range. Optimal exhaust port timing is achieved with the combination of an state-of-the-art, adjustable power valve drive. The cylinder also features two inlet positions at the rear of the cylinder where a pair of fuel injectors are mounted. This ensures efficient combustion resulting in reduced fuel consumption and emissions.

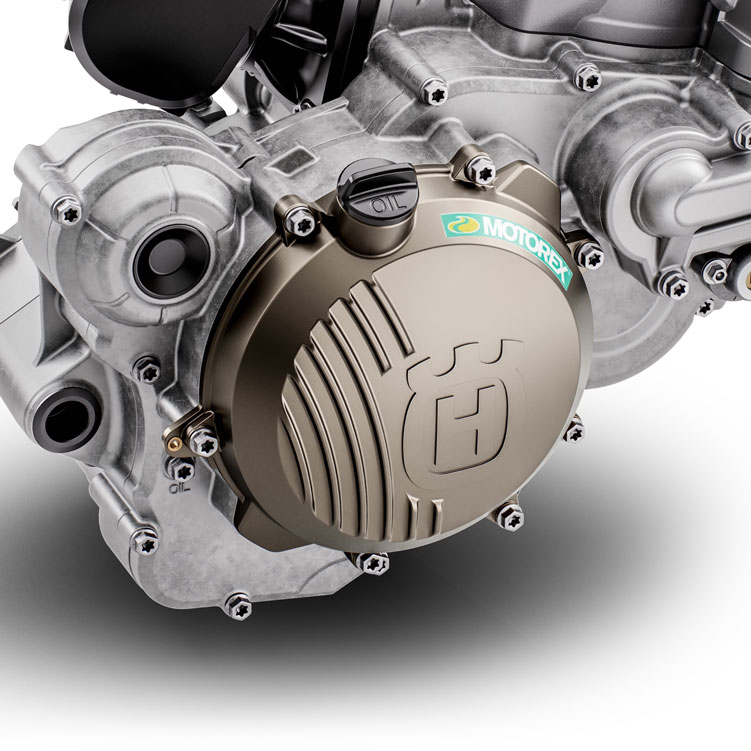

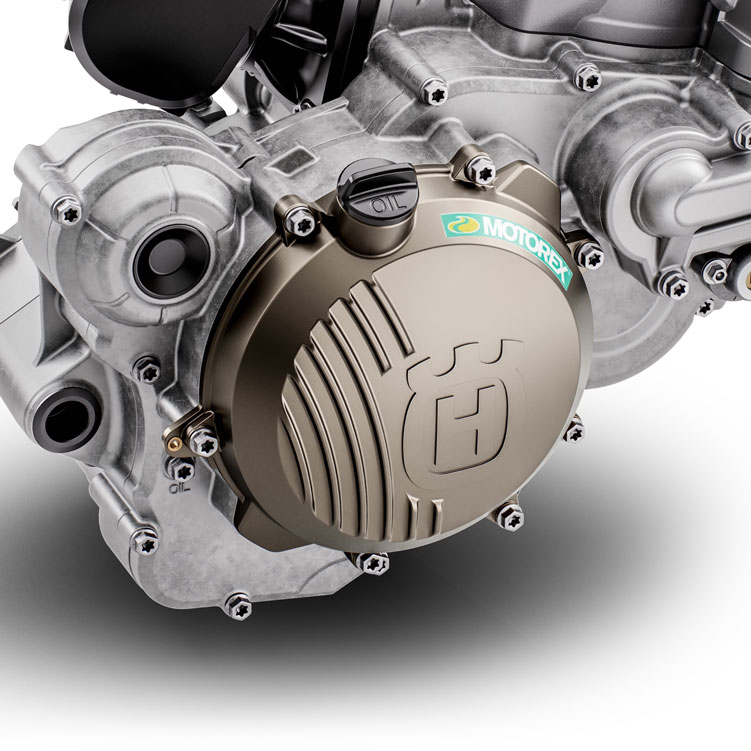

Crankcase

Designed for minimal weight, the die-cast crankcases on the TE 250 engine feature a thin-wall design. To centralise mass, the shaft arrangement has been precisely positioned to harness oscillating masses at the ideal centre of gravity. The counter balancer shaft is also specifically integrated, making for a compact design. Additionally, the water pump casing is designed to improve cooling by optimising the flow of coolant.

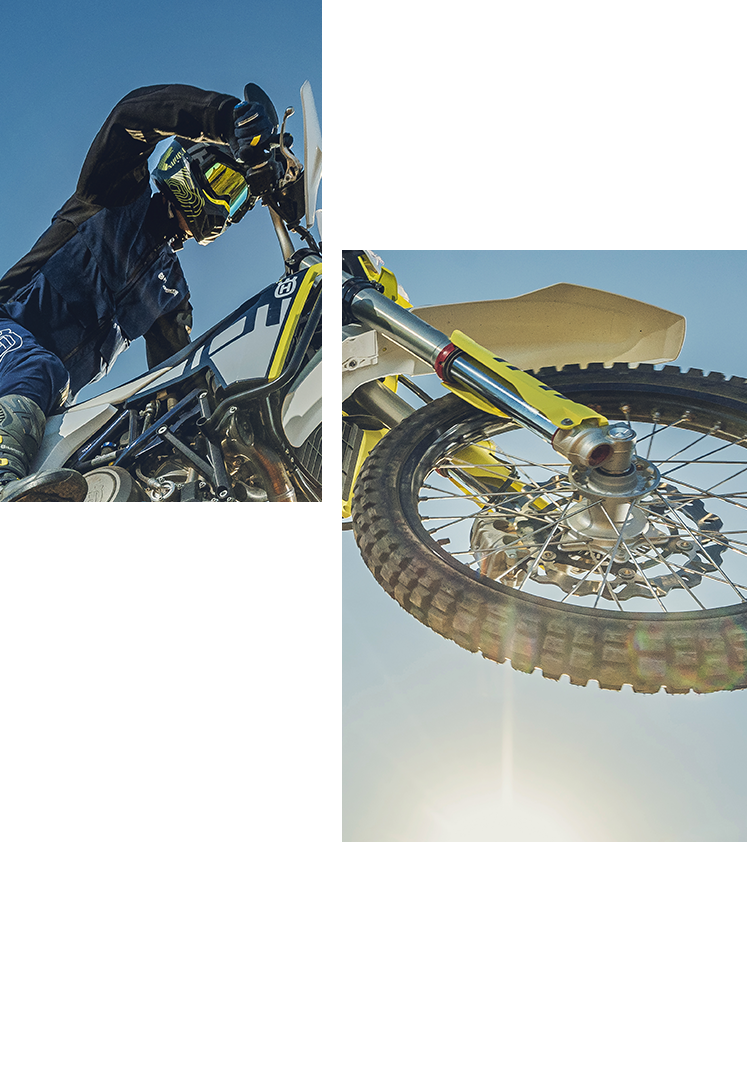

Exhaust

Tailored specifically for each model using an innovative 3D design process, the header pipe on the TE 250 offers an advanced geometry and performance. This allows for improved ground clearance, while a corrugated surface makes the header pipe resistant to impact out on the trail. The muffler also features an aluminium mounting bracket and advanced internal construction for excellent noise damping and weight saving.

Engine

Cylinder

Crankcase

Exhaust