01. Unrivalled power

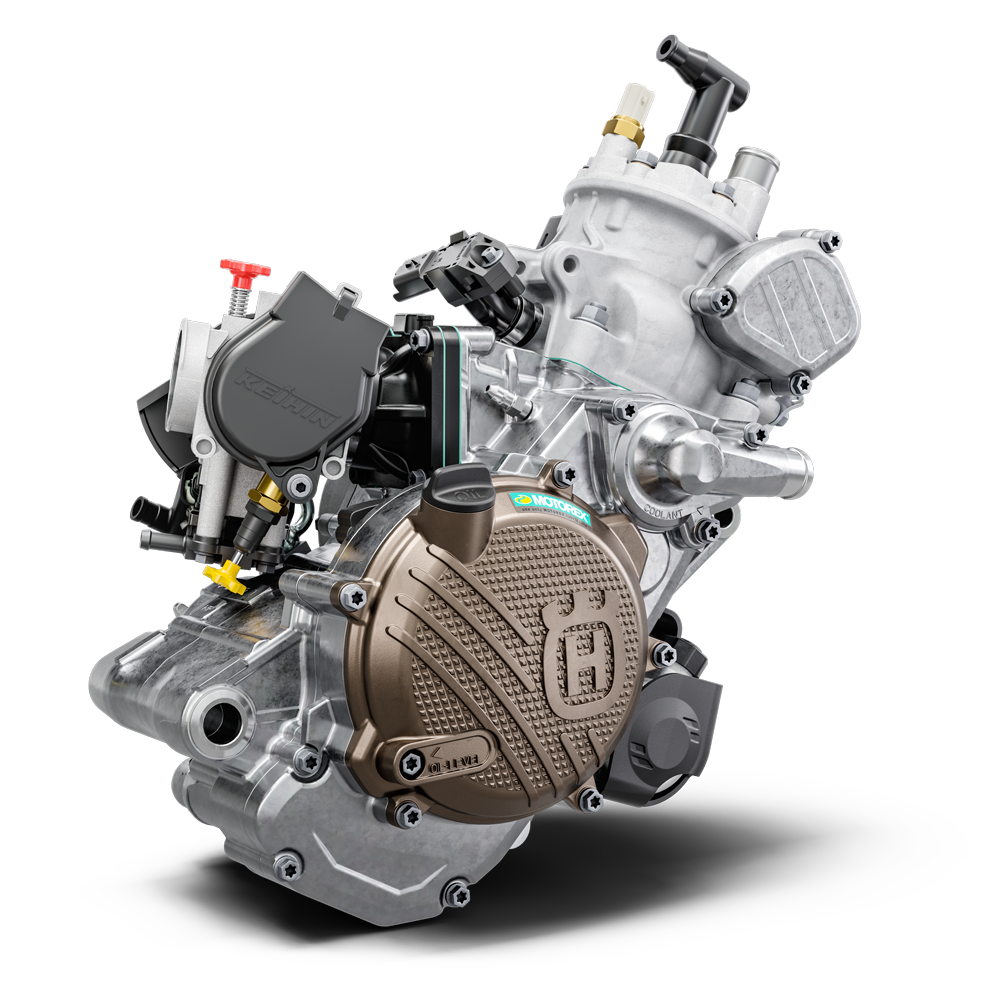

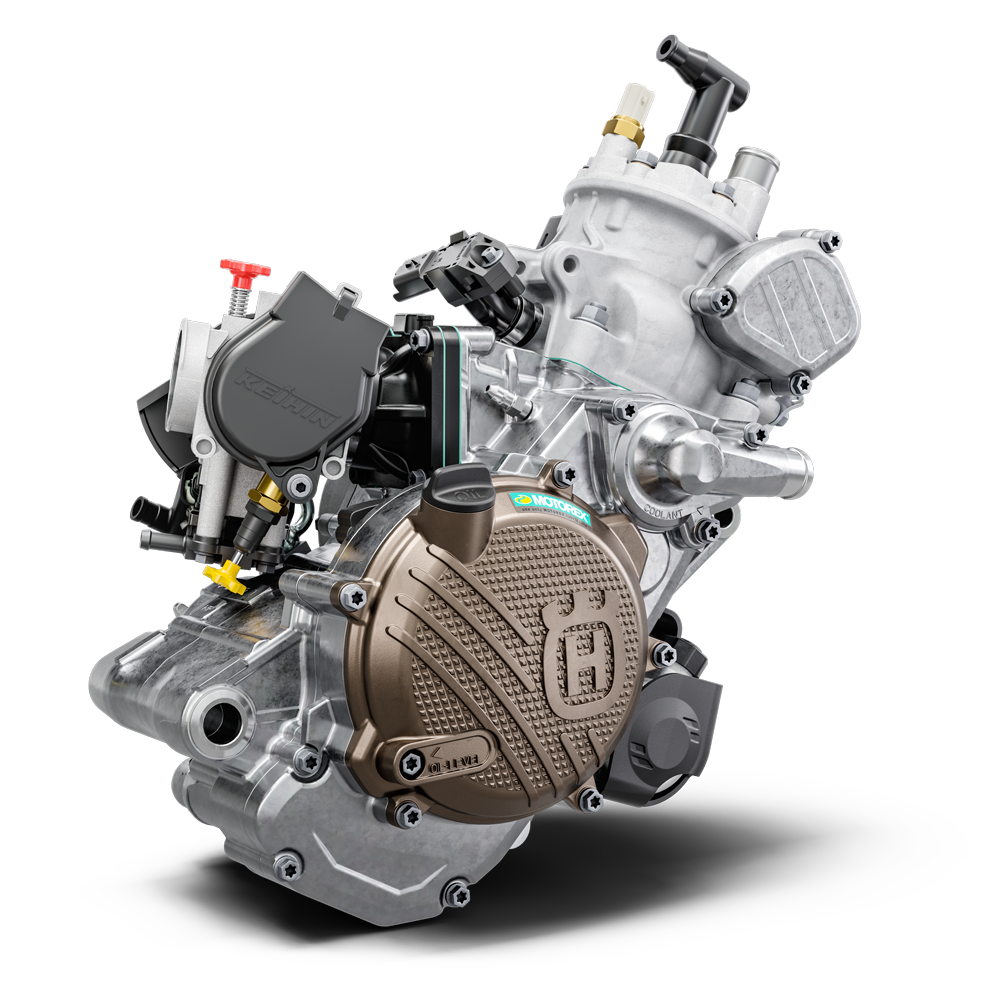

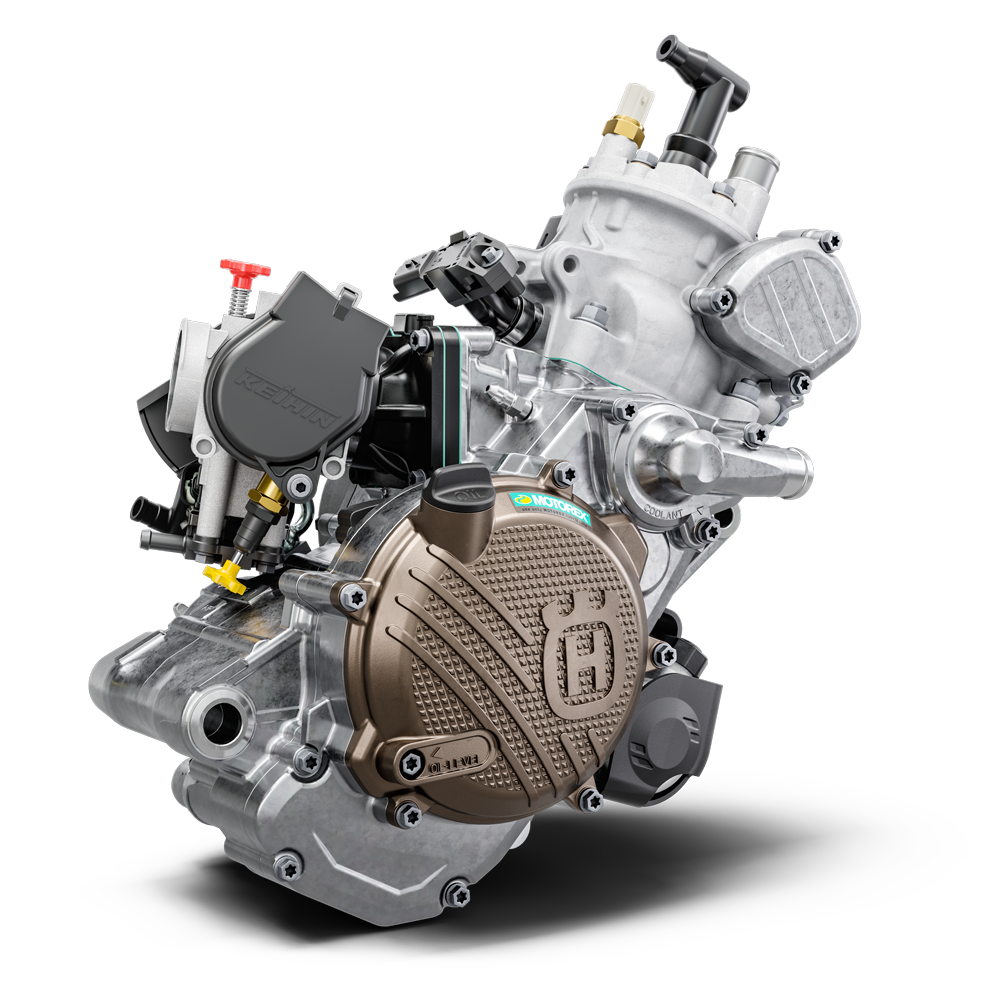

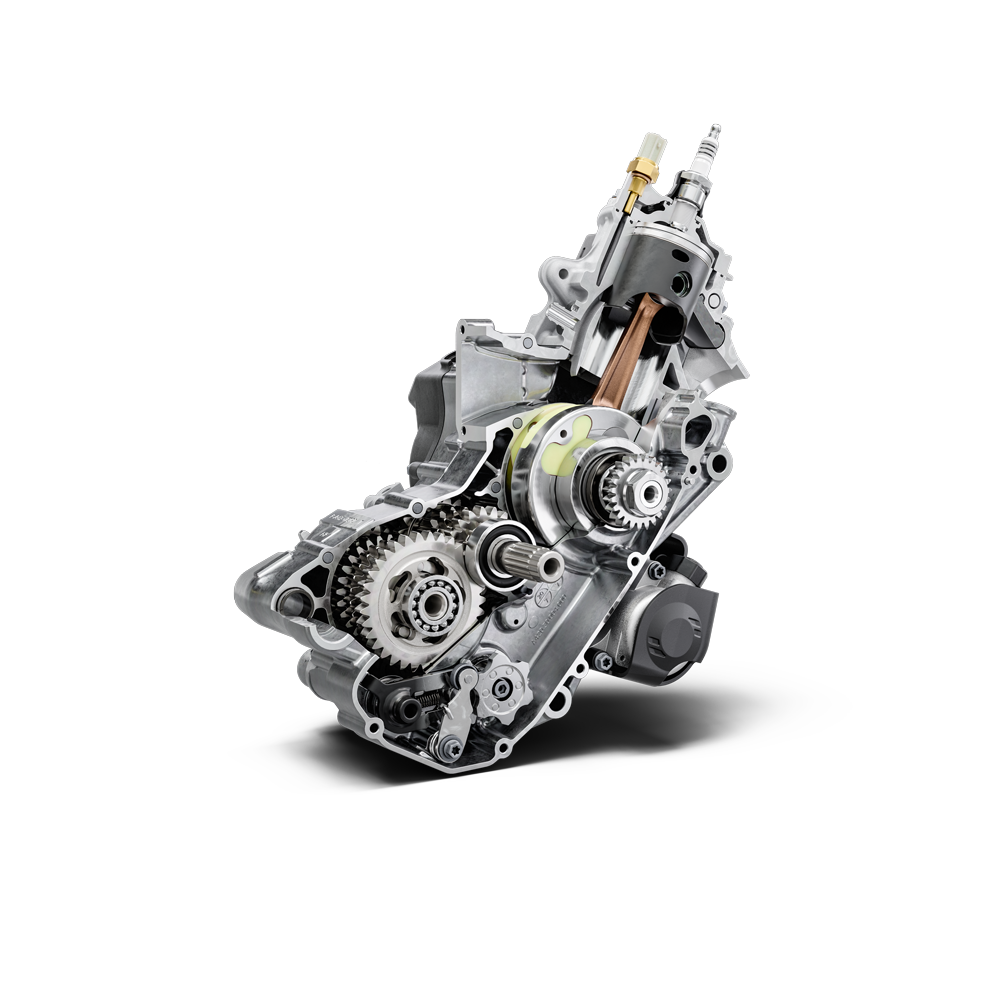

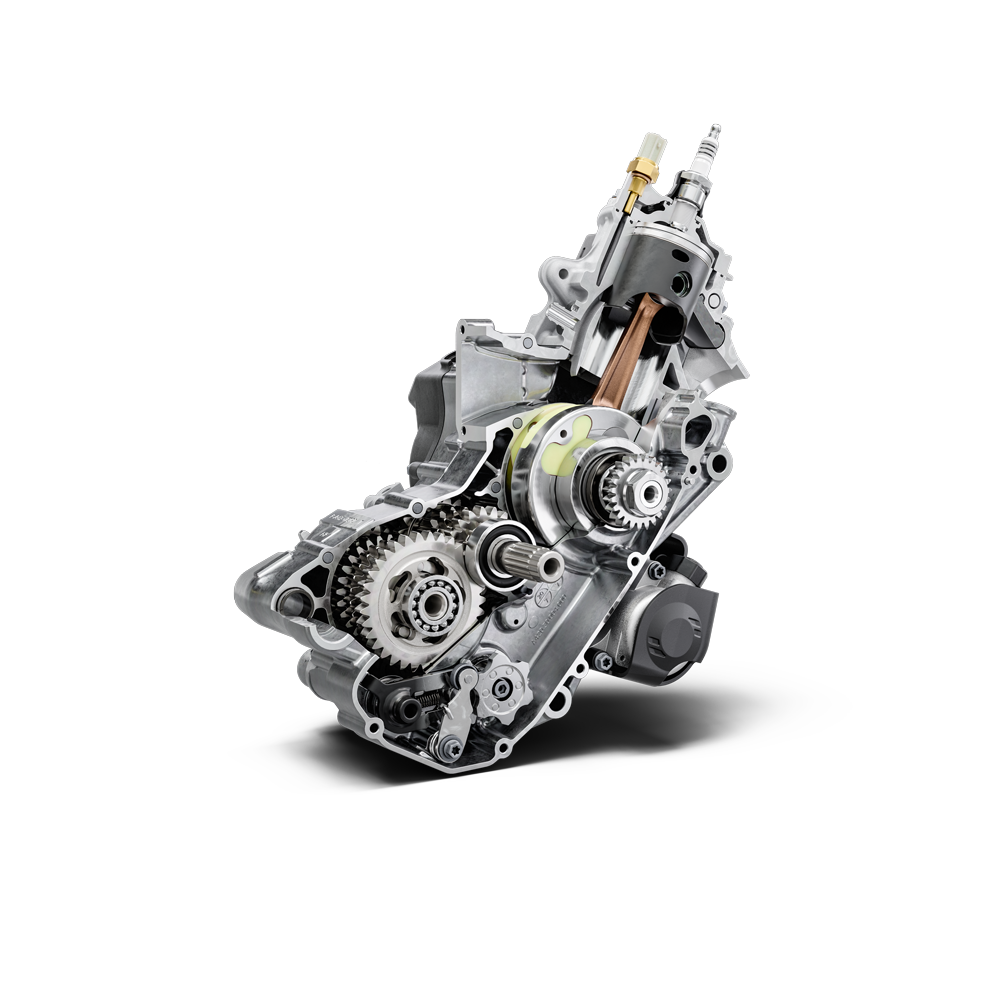

Engine

The TE 150 has inherited the same fuel-injected technology from the bigger TE 250 and 300. This adds the convenience of a 4-stroke engine by eliminating the need to premix fuel or adjust jetting for altitude. The engine also uses specific shaft arrangements, which are designed to harness the rotating mass of the engine for nimble handling. This, among other developments, makes it a lightweight and compact engine providing usable enduro-specific power while maintaining the low-cost maintenance of a 2-stroke.

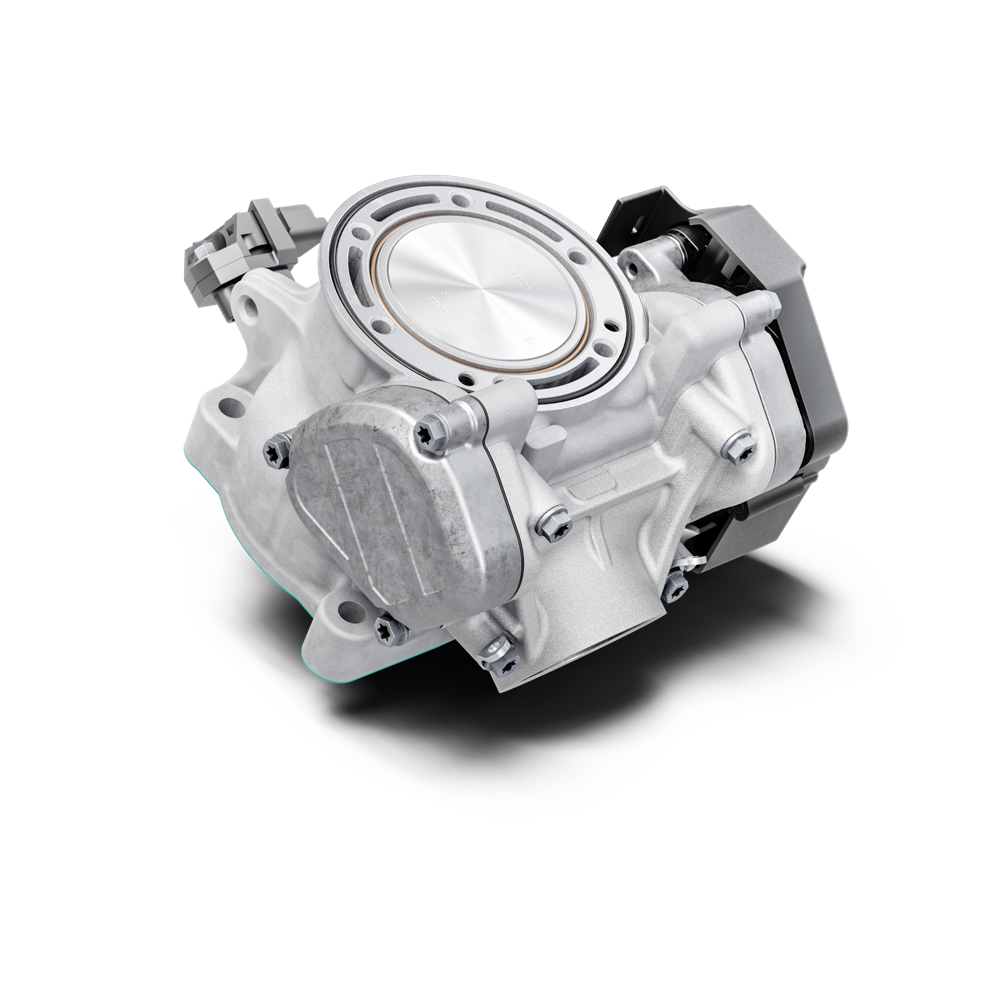

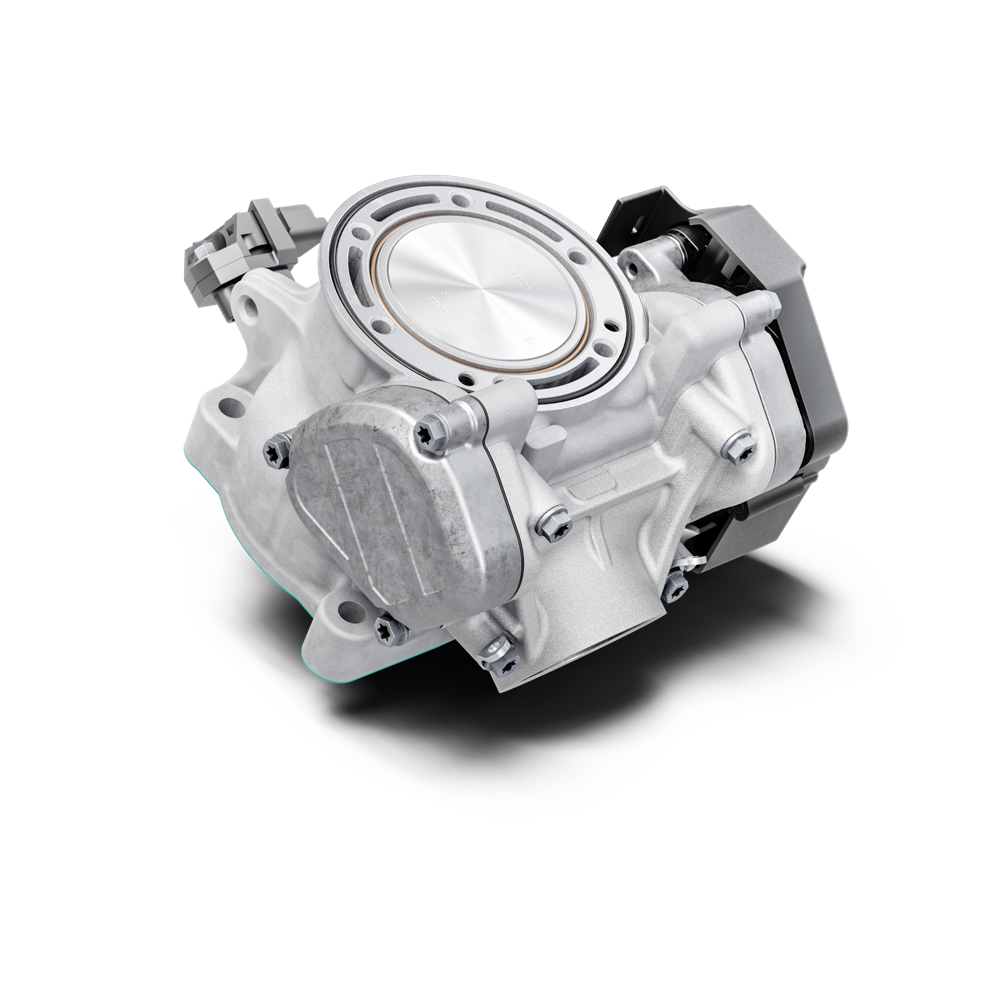

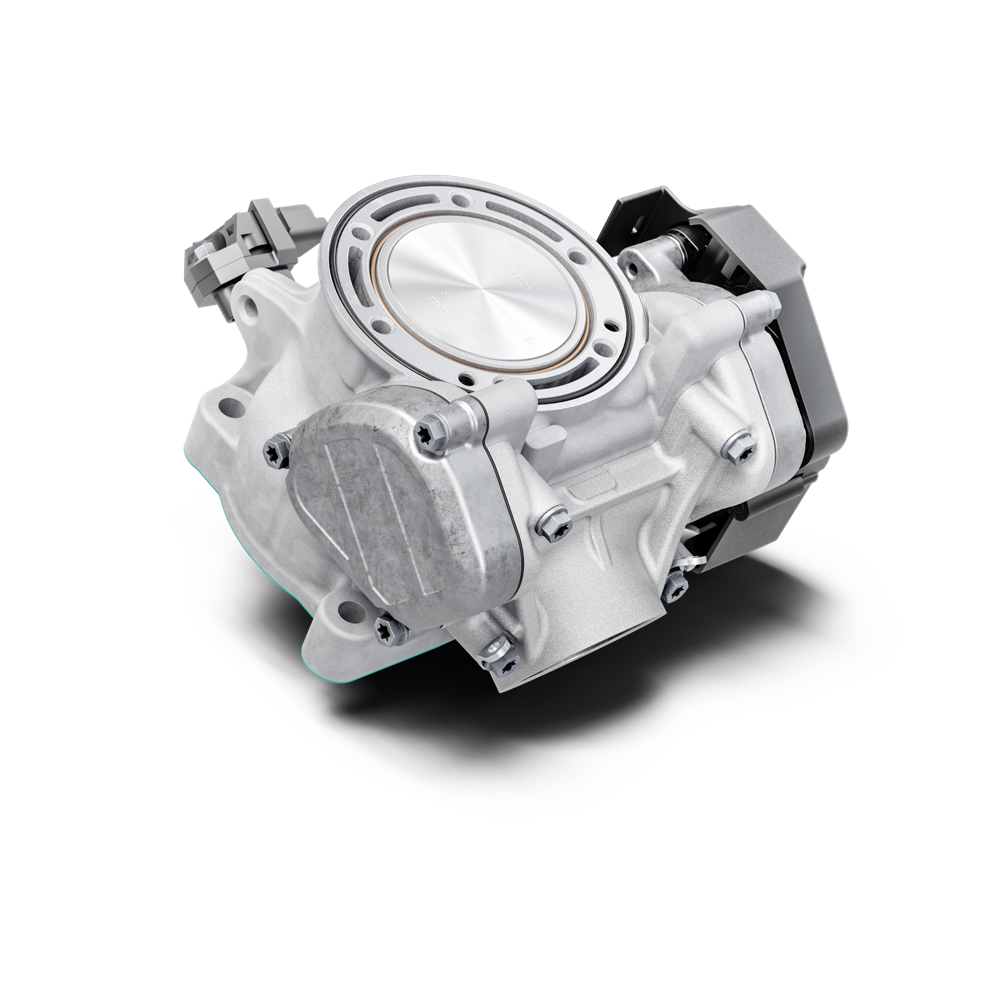

Cylinder

The TE 150 features a cylinder with a 58 mm bore and an innovative power valve design. This allows the lively 150 cc engine to deliver controllable power throughout the RPM range. The piston is designed to perfectly match the contour of the combustion chamber, delivering the highest level of 2-stroke performance. Additionally, the cylinder features injectors mounted at the inlet positions, which deliver the fuel downwards into the transfer port, guaranteeing excellent fuel atomization. This ensures more efficient fuel combustion, reduced fuel consumption and improved emissions.

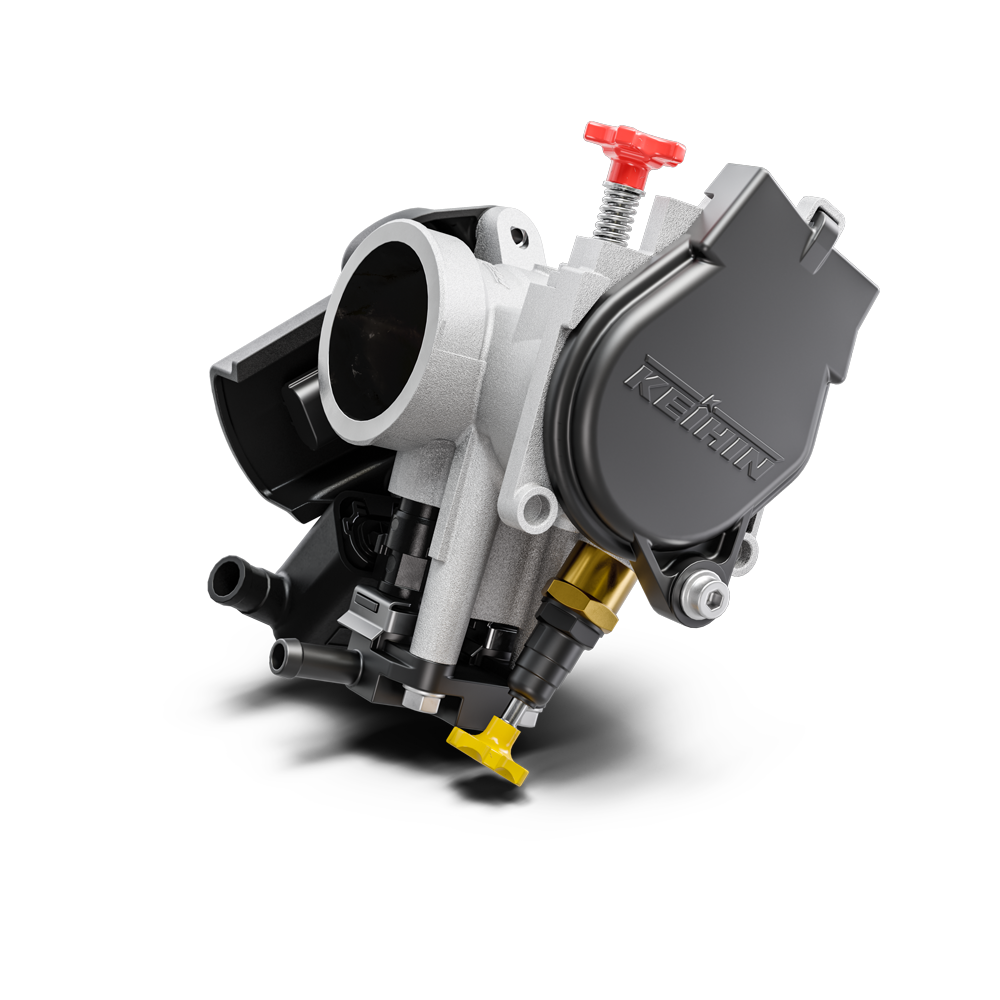

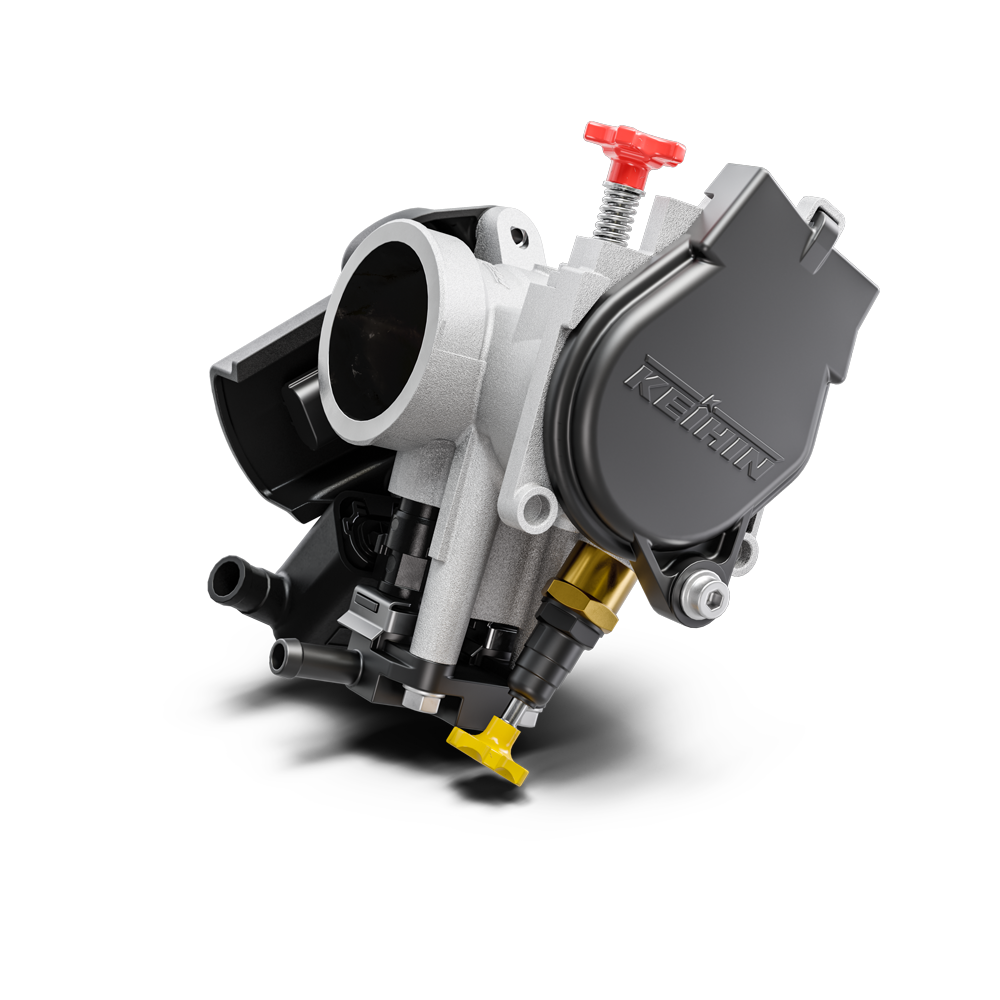

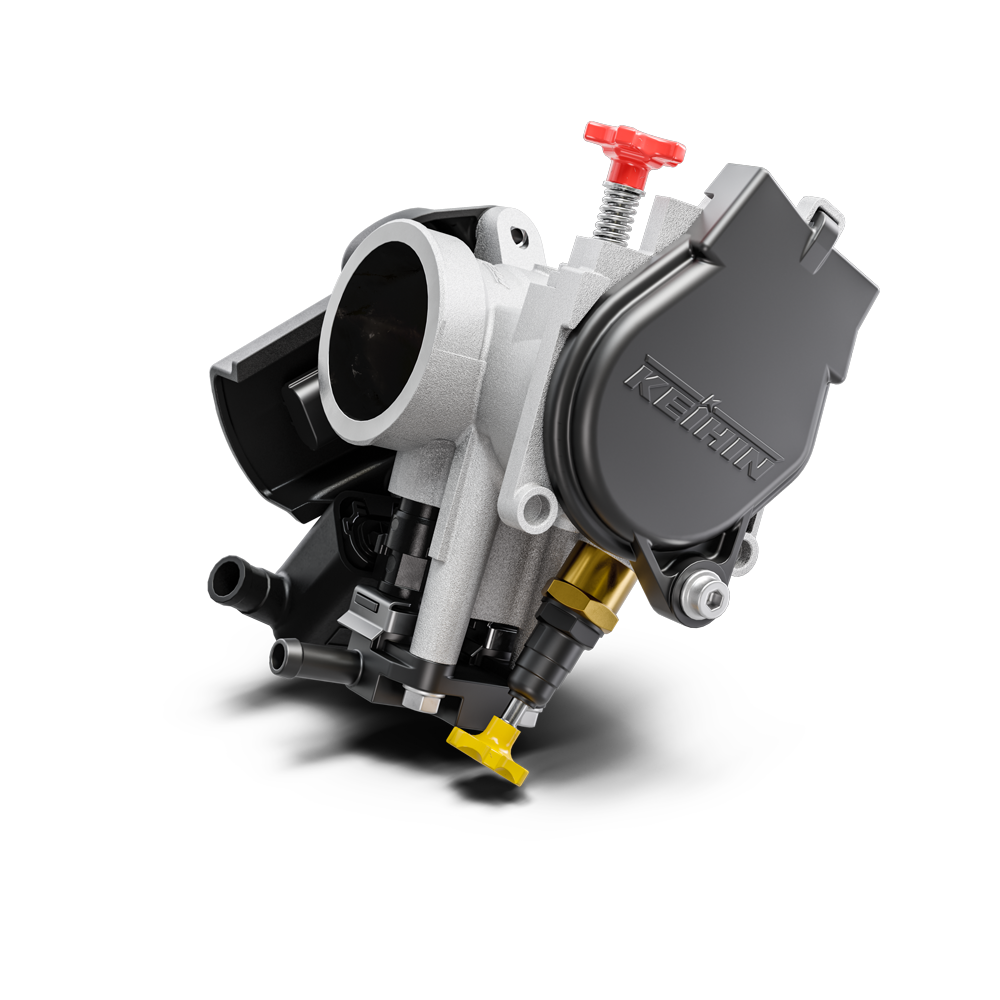

Throttle body

The TE 150 uses a 39 mm throttle body with dual injectors positioned to optimise flow for a more immediate throttle response and exceptional rideability. Idle is controlled by the throttle valve, with one low load injector and one top feed injector ensuring maximum performance. Additionally, a Throttle Position Sensor (TPS) offers reliable cold starting with the throttle valve pivoting on ball bearings for a smoother throttle action.

Oil tank

An electronic oil pump feeds vital 2-stroke oil into the engine. It is located just below the oil tank and feeds the oil via the reed cage, meaning the oil is only mixed with air at this stage. The pump is controlled by the EMS and delivers the optimal amount of oil according to the current RPM and engine load. The oil tank is connected to a filler hose which runs through the upper tube of the frame to a filler cap conveniently located for easy refills.

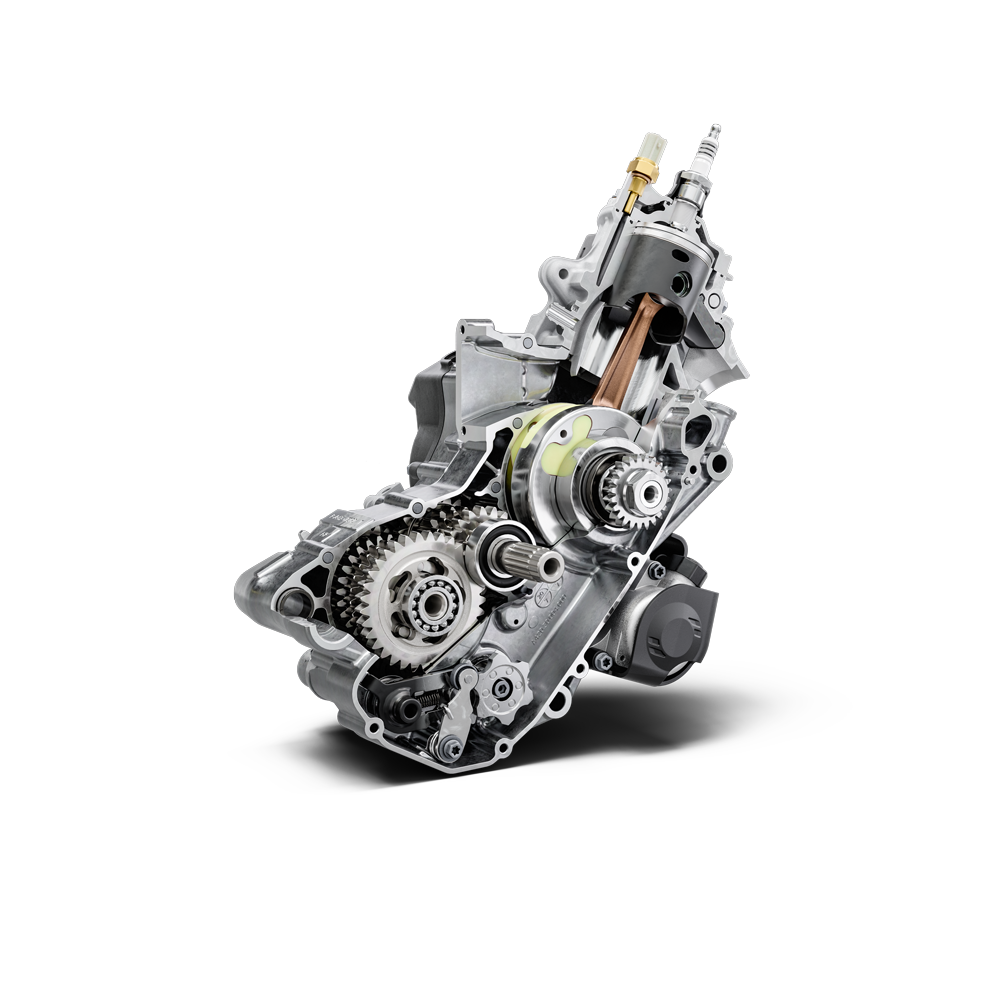

Crankcase

Designed for minimal weight, the crankcases on the TE 150 engine feature a thin-wall design. To centralize mass, the shaft arrangements are precisely positioned to harness rotating masses at the ideal center of gravity, while improved sealing is taken care of by the reed block which features optimized carbon fiber reed petals.

Exhaust

Tailored specifically for the TE 150 using an innovative 3D design process, the header pipe ensures unrestricted performance and offers improved ground clearance to reduce the risk of impact damage out on the trail. The silencer also features an aluminium mounting bracket and advanced internal construction for excellent noise damping and weight saving.

Engine

Cylinder

Throttle body

Oil tank

Crankcase

Exhaust